Ultra-High Performance Concrete

Ultra-High Performance Concrete (UHPC) is a structural material that exhibits compelling structural behaviors. In comparison to conventional concrete, UHPC offers sustained postcracking tensile resistance, along with an increased compressive strength, an increased elastic modulus, and a decreased susceptibility to liquid permeation.

The mechanical and durability properties of UHPC make it an ideal candidate for use in developing new solutions to pressing concerns about highway infrastructure deterioration, repair, and replacement.

The mechanical and durability properties of UHPC make it an ideal candidate for use in developing new solutions to pressing concerns about highway infrastructure deterioration, repair, and replacement.

Since 2000, when UHPC became commercially available in the U.S., a series of research projects has demonstrated the capabilities of the material, and a handful of state DOTs have deployed UHPC components within their infrastructure, with many more are actively considering its use.

In its effort to advance the state of the practice related to UHPC, FHWA recently published "Structural Design with UHPC", a report that provides information on the structural design of bridge components.

The co-published "UHPC Link Slab Design Example" provides a guide on the use of UHPC link slabs for preserving highway bridges.

Watch the video below to learn more about UHPC & its applications

UHCP Properties

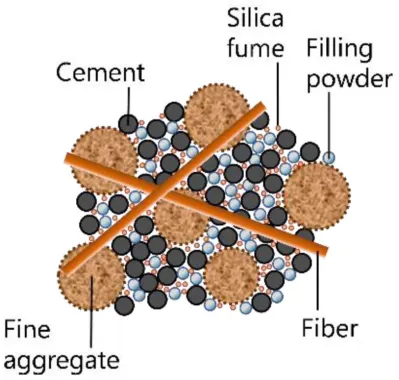

UHPC is a cementitious composite material composed of an optimized gradation of granular constituents, a water-to-cementitious materials ratio less than 0.25, and a high percentage of internal fiber reinforcement.

Its mechanical properties include compressive strength >17,500psi (120 Megapascals) and sustained postcracking tensile strength >750 ksi (5.2 MPa).

UHPC has a discontinuous pore structure that reduces liquid ingress, significantly enhancing durability as compared to conventional concretes.